Building Services Engineering and Refrigeration Engineering

The problem:

The pressure test in a refrigeration plant is intended to ensure that the system withstands the operational pressure loads. It is important that the system is leak-tight and that no refrigerant can escape. On the one hand, leaks cause a drop in the refrigerating capacity of the plant and on the other hand they can cause environmental damage, as refrigerants contain fluorine or chlorine.In order to prevent such “dangers”, the instruments have to withstand the strong vibrations of the system. Furthermore, the pulsation of the medium must be reduced.

Our solution:

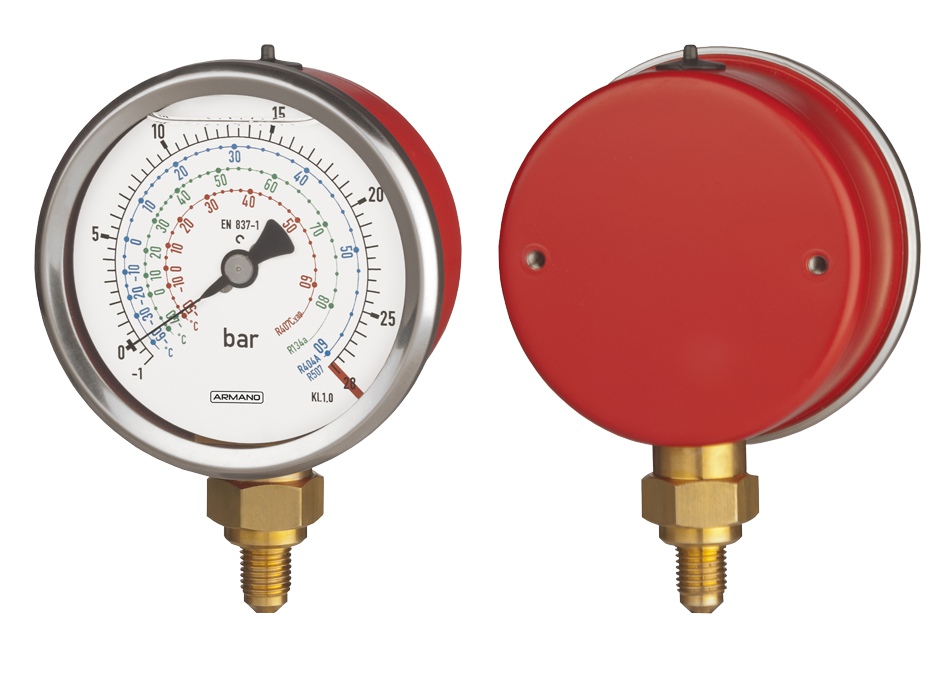

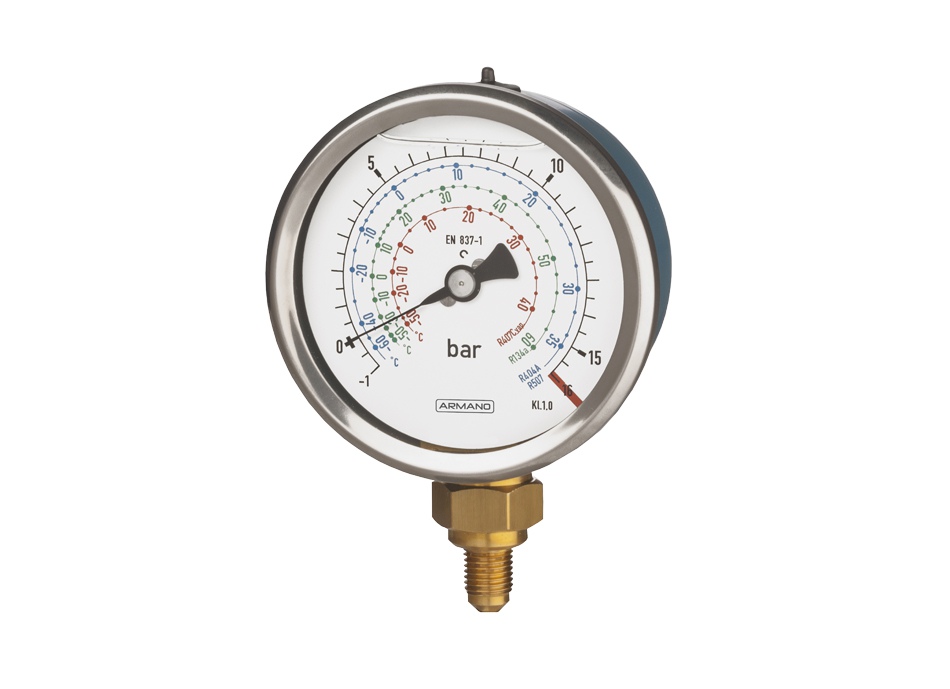

Our instruments are filled with glycerin. This dampens strong vibrations. Refrigeration pumps cause pulsations (of the medium) in the tubing and thus dynamic loads on the pressure gauges. A restrictor screw with a small orifice in the inlet port of the pressure gauge “calms” the pulsations and thus the pointer movement. This significantly extends the service life of the pressure gauges.For this application one pressure gauge is used for the low-pressure side (blue case) and one pressure gauge is used for the high-pressure side (red case).

- Pressure range*: -1 / +16 bar

- With temperature scale acc. to refrigerant (e.g.: R 134 A, R 404 A, R 407 C, R 507, R 744)

- Process connection: 7/16"-20 UNF bottom

- Restrictor screw Ms with orifice 0.3 mm

- Mounting of the instrument: 2 blind rivet nuts M4, 10 mm deep, 60 mm distance in back of case

* other pressure ranges upon request