Shipbuilding Industry

Pressure measurement in the offshore area

Subsea gauge as control instrument to a depth of 3,000 m (10,000 ft) (AppBe_SB_025)

for manufacturers and operators of remote-controlled, camera-monitored and hydraulic tools or devices for the operation of subsea pipelines or drilling equipment in the offshore area

The problem:

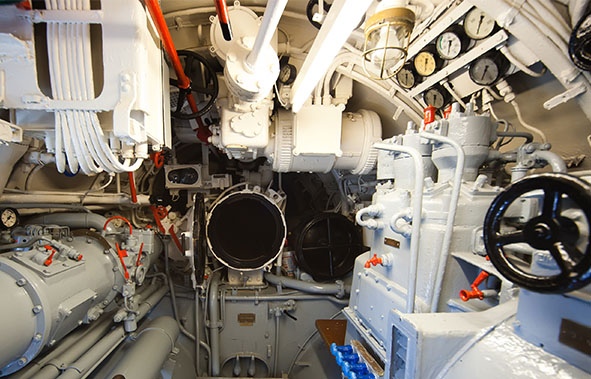

Difficult geohydraulic conditions are prevailing when drilling and producing oil and gas. The rock layers are under a high pressure caused by fluids in rock pores. Due to oil, gas and water critical conditions can develop, especially during deepwater drillings.Blow-out-Preventers (BOPs) are installed directly above the well to make the drilling safer. BOP are a series of shut-off valves. These are controlled and activated by pressure gauges. In case of an oil or gas blow-out, the BOP is designed to seal the well and thus prevent the oil from spilling into the ocean. BOPs are very large and difficult to install. At great depths, the difficulties increase, also with regard to the functionality of the instruments..

In addition to BOPs, there are also other fields of application in the oil and gas production where pressure gauges are used under water:

- Production trees − serve as well closure after a successful drilling for crude oil or natural gas

- Remotely Operated Vehicle (ROV)

- Subsea pumping facilities

Our solution:

As the drilling takes place in ever greater depths, the functionality of the instruments has to stand the test. Our pressure gauge, especially designed for subsea application, withstands these difficult conditions to a water depth of 3,000 m (10,000 ft). But also salt water must not corrode the instruments, which is why we use appropriate materials to ensure the contin-uous operation of the instruments in this environment. Under such harsh process conditions our instrument operates accurately and reliably.The displayed values are transmitted by cameras and still have to be easily readable. Due to our special pointer and scale design, the values can be read precisely, even in great water depths.

Our advantages at a glance:

- Applicable to a water depth of 3,000 m (10,000 ft)

- Case filling for robust process conditions due to primarily hydraulic applications

- Black dial, white scale and pointer for exact reading of the indicated values

Our instrument in detail:

To a water depth of 3,000 m (10,000 ft):Bourdon tube pressure gauge: RChG 100 – 3 rFr

- Accuracy class 1.0 (DIN EN 837-1)

- Bayonet ring case stainless steel 304

- Case filling glycerin

- Nominal case size 100 mm (4")

- Wetted parts stainless steel 316L

- Case configuration lower back connection (r)

- Front flange for panel mounting (Fr)

- Pressure range e.g.

- 0 – 160 bar to 0 – 2,500 bar

- 0 – 2,000 psi to 0 – 35,000 psi

- Process connection ¼" NPT

- Window acrylic glass

- Dial aluminum black, scale and pointer white

- Options:

- case stainless steel 316L

- other case configurations

- other process connections, e.g. high pressure connection male and female thread e.g. for ¼" tube with 60° cone

Download:

Differential pressure measurement in submarines

Pressure monitoring – duplex pressure gauge with differential pressure indicator (AppBe_SB_027)

for submarine yards, operators of differential pressure measuring instruments

The problem:

For differential pressures, in some cases it shall be obvious at the first glance whether the pressure is within a certain range. Furthermore, the pressure gauge must remain readable even in the dark (without lighting).Our solution:

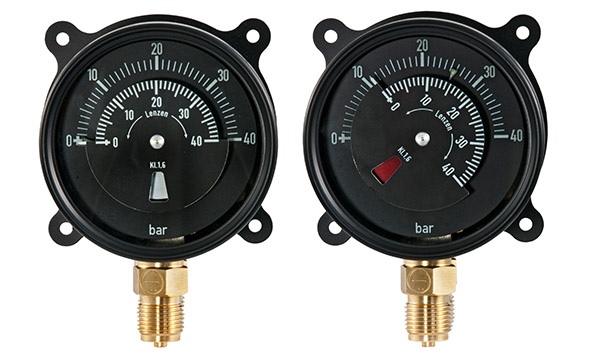

Duplex pressure gauges with two special indicator dials, black case and luminescent scale. A red field appears at a certain pressure range, as requested by the customer. Additionally, the white scale is coated with a luminescent colour, which ensures the visibility in the dark.

Differential pressure gauge DiRCh 100 – 1 Rh

- Mounting device according to your requirements

- Case colour fitting to the surroundings

- Indicator dial design fitted to the requirements on site

- Also available in stainless steel