Energy

The problem:

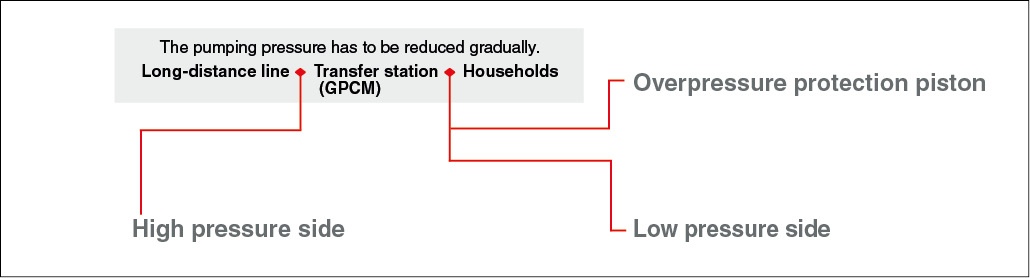

Natural gas is carried under pressure. When the natural gas is extracted from the long distance pipeline, the pressure has to be reduced in order to distribute it to transfer stations. From these transfer stations, gas lines branch out until they reach the individual households. That means, the pressure of the gas also has to be continually reduced.

Our solution:

Special systems, such as gas pressure control and measuring systems (GPCM), allow for the observance of the flow pressure dependent on the flow rate. In the GPCM, both the high pressure (Bourdon tube pressure gauge) and the low pressure (capsule gauge for low pressure) have to be measured. Although over-range protection devices are installed in the low-pressure area, our capsule gauges for low pressure are often applied 3-times or 10-times overrange protected.

Bourdon tube pressure gauge RCh 100 – 1

- 0 – 4 to 0 – 100 bar (0 – 60 to 0 – 1,500 psi)

- Bottom connection G ½ B (½" BSP)

- Accuracy class 1.0

- Test report 2.2 according to EN 10 204

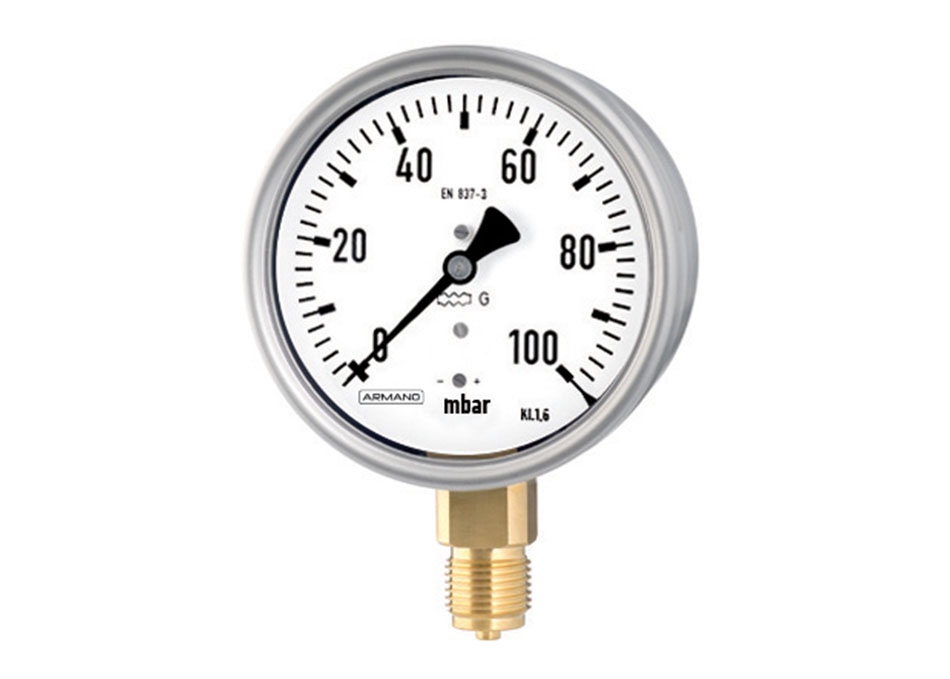

Capsule gauge KPCh 100 – 1

- 0 – 60 to 0 – 400 mbar (0 – 800 to 0 – 5,000 psi)

- 3-times or 10-times overrange protected

- Accuracy class 1.6

- Accuracy class 1.0 possible

- Test report 2.2 according to EN 10 204

- Brass version: PN 500 bar

- Instrument connection: clamping sleeve - connection

- Process connection: G ½